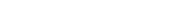

Polycarbonate Vacuum Forming:

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications.

1. Production:

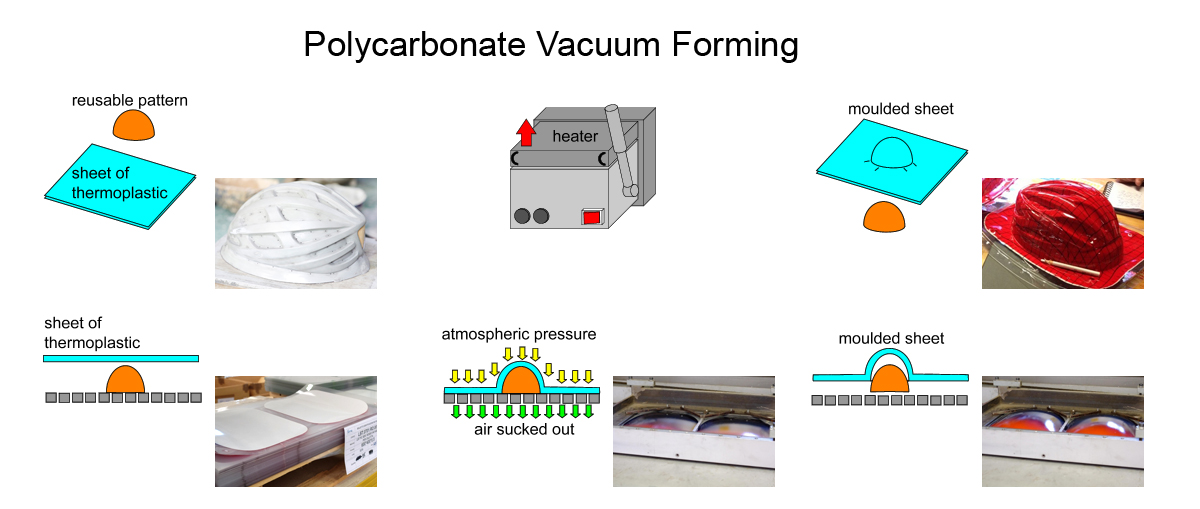

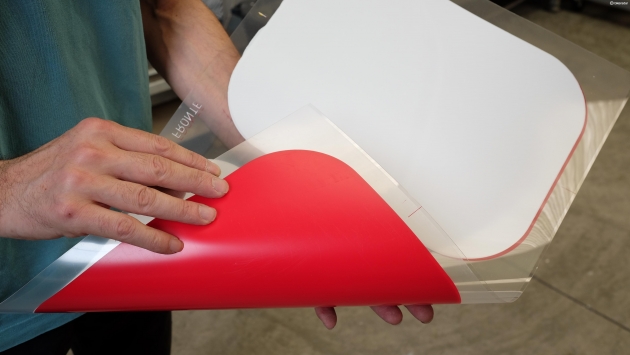

It is one of the thermal forming methods of thermoplastic plastic. Clamping the sheet or plate material on the framework of vacuum forming machine, through the air channel mold side, with its vacuum adsorption to the mold, after a short period of time of cooling, molding plastic products are produced.

2. Advantage:

This is a new progressive technology that the products are quite light. Mainly used for helmets(bicycle, kids, skateboard, horse, etc), daily packaging(food, toy), lighting, advertising, decoration, electronics, electric appliance industries, etc.

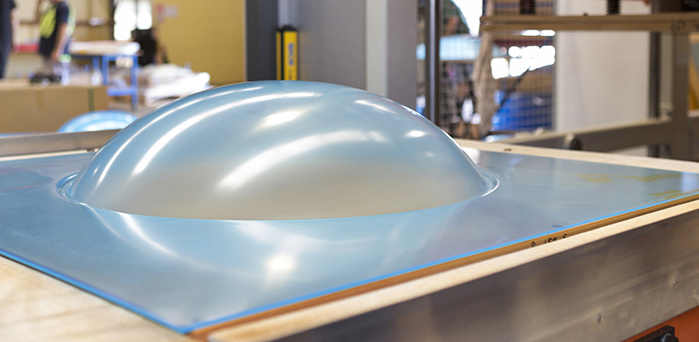

Although much polycarbonate sheets have good adhesion to most printing oil, still, we tend to choose one that is effective.

Type of mesh, Squeegee, Stencil, these are most important variables for the printing of polycarbonate sheet. Of course, the amount of printing oil will determine the final graphics on the sheets.

We choose transparent PC sheet material because transparent PC sheet is easy to coloring. the printed pattern is clear and durable. Besides, it will not fade after long-term use.