Prototyping

A prototype can help to add value to a project as well as credibility.

Aurora has a team of design engineers that specializes in prototyping. Our experienced prototyping team help customers turn great ideas into successful helmets quickly and expertly.Our prototyping team members have great passion for every project we take on, and you will find that in our work. We don’t stop until we are satisfied with what we are delivering -even if it means burning a great deal of midnight oil! Until now our professional prototyping team has already worked on over 3000 helmet prototyping projects for the many international brands, like Bell, Limar, Giant etc..

According to the function of the prototype there are different development stages which require different types of prototypes.

Appearance prototyping

Appearance prototype: The main purpose is to test product appearance design. It has strict requirement on the appearance, but these prototyping don’t ask high standards on color or internal processing.

Structure prototyping

The main purpose is to test whether a product is reasonable or not. The structure prototype has a high requirement for size, especially in foreign countries.

Final workable prototype

The final workable prototype is the closest you will get to the real helmet, including appearance, structure, and function. So it can be thought as the unlisted finished product. The final workable prototype is the most difficult one among the three prototypes.

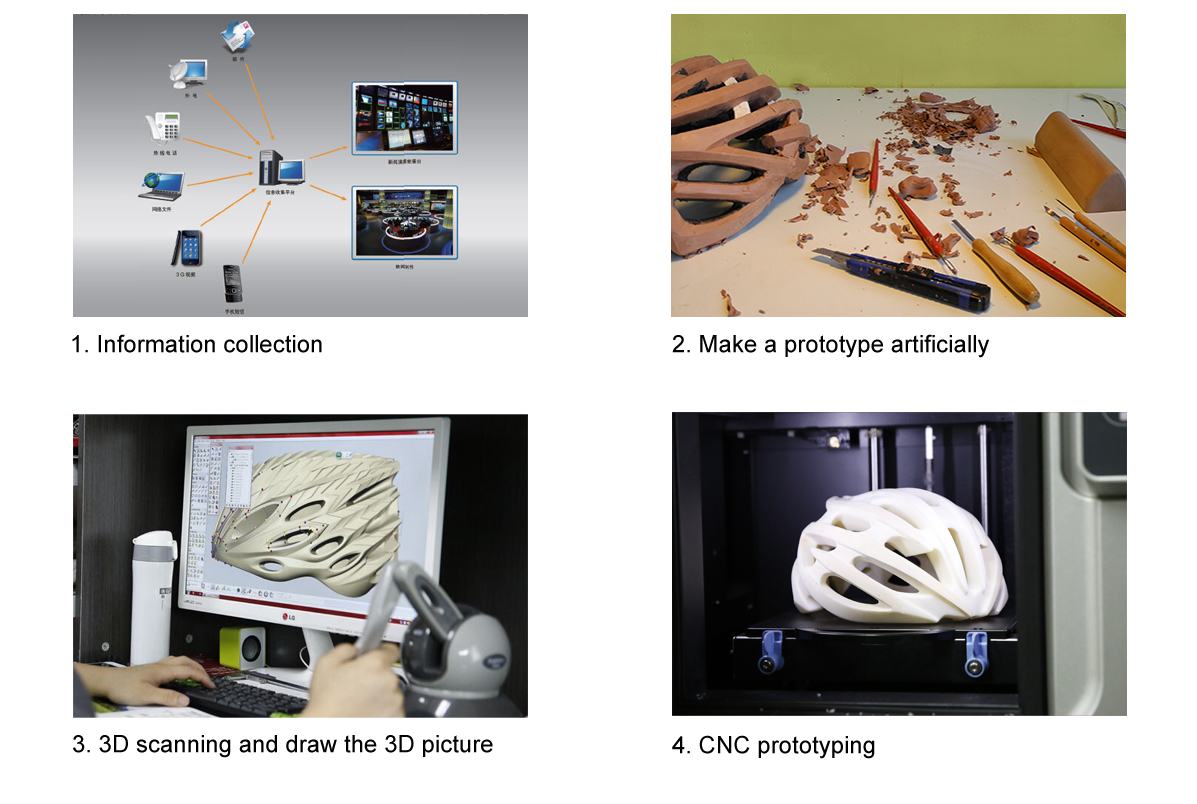

How to develop a product prototype?

How we control the prototype quality?

Our analysis and simulation processes are fully integrated into our prototyping. High specification simulation software provides the means for our design engineers to carry out powerful computational analysis and validation allowing us to deliver innovative solutions.

And we have our own inner test lab. In the development process, we can predict the safety performance of the product in advance. Timely revise it, which can greatly shorten the product development cycle and speed up the progress of the new product launch. What’s more, it can save you more cost on testing the product in the third testing lab and protect your own design as well.

Why is a product prototype necessary?

You will need the product prototype to prove that your concept works and that the product design can translates into a workable model.The product prototype may better demonstrate the product also.

How is an invention prototype useful for manufacturing?

Prototype is a beginning, which bring your design into reality. In order to meet the product specification and pass the product safety certification, our experienced technical team will improve all the deficiencies of your design by evaluating the 3D function prototype, and find a final workable product prototype for manufacturing.